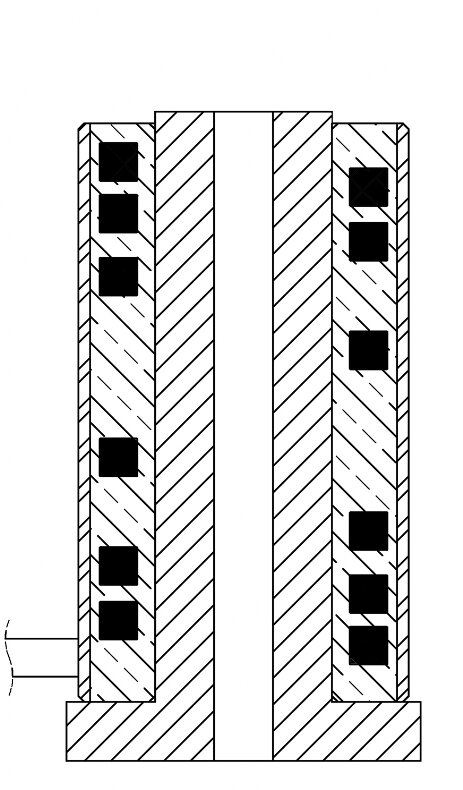

Homogenious heat transfer

Full surface contact with the heating element

Longer life

Heat absorption

Precise heat control

Energy Saving (longer on/off intervals)

Why cast-in nozzle heaters instead of conventional coil heaters ?

Coil heaters may seem as a sufficient and relatively cheaper solution for nozzles.

However, there are some crucial disadvantages of conventional coil heaters.

Coil heaters are;

Expanding in diameter, when heated

Partially contacting the surface of the nozzle

Because of its low mass, it heat losses are very high

More than half of the heater surface does not touch anywhere due to its cross section

Due to heat losses, it is not possible to keep the desired temperature during injection

Frequent on/off intervals

Cast-in Nozzle heaters does not have these disadvantages.

Ultimately, its expected life time is 3 times more than a conventional coil heater.

Full surface contact prevents the cool-down of the plastic during the injection.

Because of its relatively higher mass, it absorbs and contains the heat for a long time. Therefore, it is possible to keep the desired temperature anytime.

Also on/off intervals are longer which extends the life time of the heater.

We strongly recommend cast-in nozzle heaters for high temperature plastics.