Why Cast-in Heaters?

When compared with conventional heaters:

The cast forms a single body which makes heating elements surrounded by the melted material (aluminium)

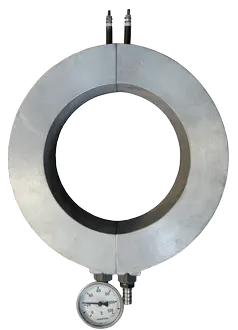

When the heating elements inside of the casted aluminium are powered up, it heats up the whole body

Cast-in heaters are massive and solid, thus when it has reached the desired temperature, it keeps the heat homogeneously

Because of the mass of the cast-in heaters, on/off intervals are much longer than conventional heaters, which makes the cast-in heaters energy saving and extends the life of the heating elements significantly

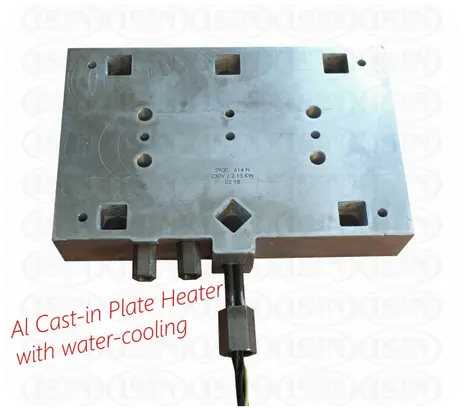

Our cast-in heaters includes stainless steel tubes for water-cooling, which is much better and efficient than air-cooling

With the combination of heating & cooling, it is possible to keep the temperature with high precision

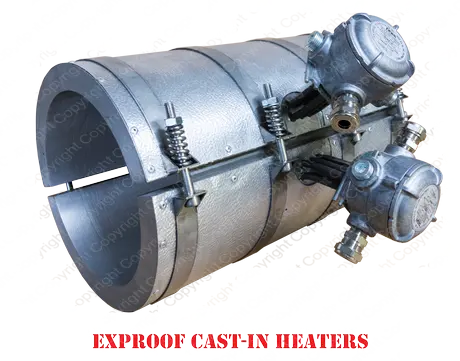

Cast-in heaters are machined according to the dimensions of the barrel

- Cast-in heaters without cooling

- Cast-in heaters with water-cooling

- Cast-in heaters with air-cooling (Finned Design)

- Cast-in cooling (without heating)

Homogeneous heat transfer

Full surface contact

Longer life

Heat absorption

Water cooling

Precise heat control

Energy Saving

Up to 450°C (842°F) Surface Temperature. (for higher temperatures, prefer Brass material)

Custom cast shrouds are available upon request